The Showroom: A Full-Scale Demonstration

Faced with competitiveness challenges and the requirements of the European PPWR regulation, the industry has had to combine operational performance with sustainable transition.

Prod&Pack 2025 rose to this dual challenge with its Showroom: a veritable mini-factory producing packaged products under real conditions, set up at the heart of the exhibition.

5 workshops in operation

Organised by packaging material, these workshops provided a live demonstration of concrete solutions to industrial and environmental challenges.

PLASTICS Workshop

Plastic, yes, but single-material and high-speed! A bag made from 70% recycled plastic was presented in operation in the Showroom.

GLASS Workshop

Visitors were able to discover an all-in-one line combining improved work ergonomics and space savings in workshops.

METAL Workshop

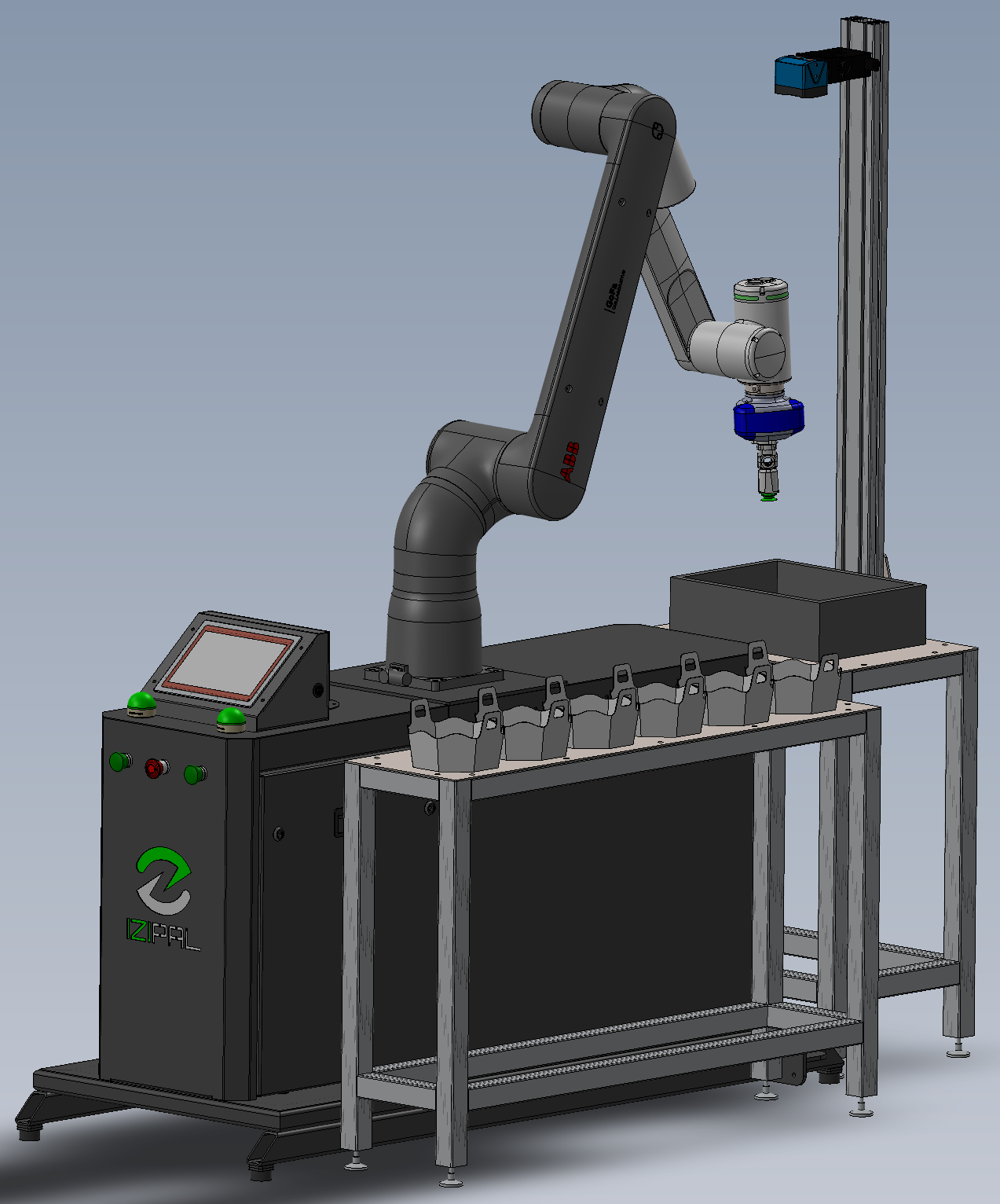

The Showroom highlighted an ergonomic crimping machine combined with a cobot to facilitate the work of operators, as well as a solution for sealing stainless steel trays to meet the challenge of reuse.

PAPER CARTON Workshop

No fewer than four technologies were presented: a compact cartoning machine suitable for confined spaces, alternative packaging solutions to plastic, hybrid tray sealing, and high-speed flowpack sealing.

WOOD Workshop

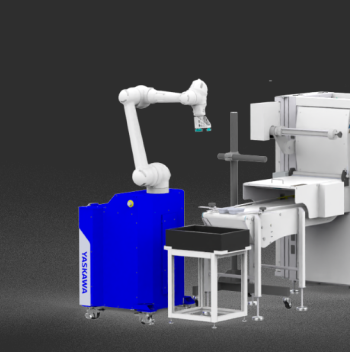

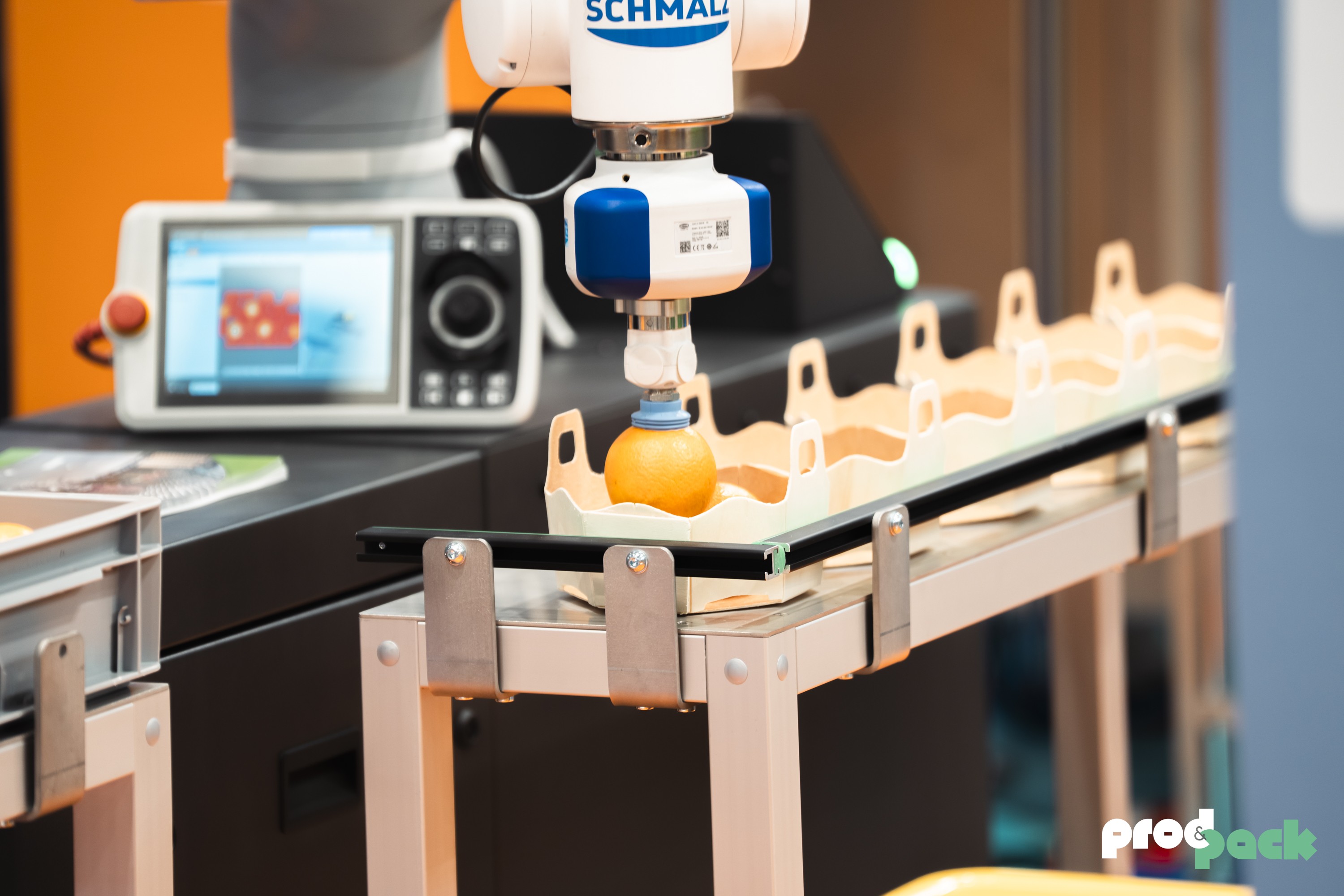

A new-generation collaborative robot was demonstrated in real conditions. Without compromising safety or productivity, it filled wooden trays in perfect synergy with the operator.

A high-performance, automated and digitalised mini-factory

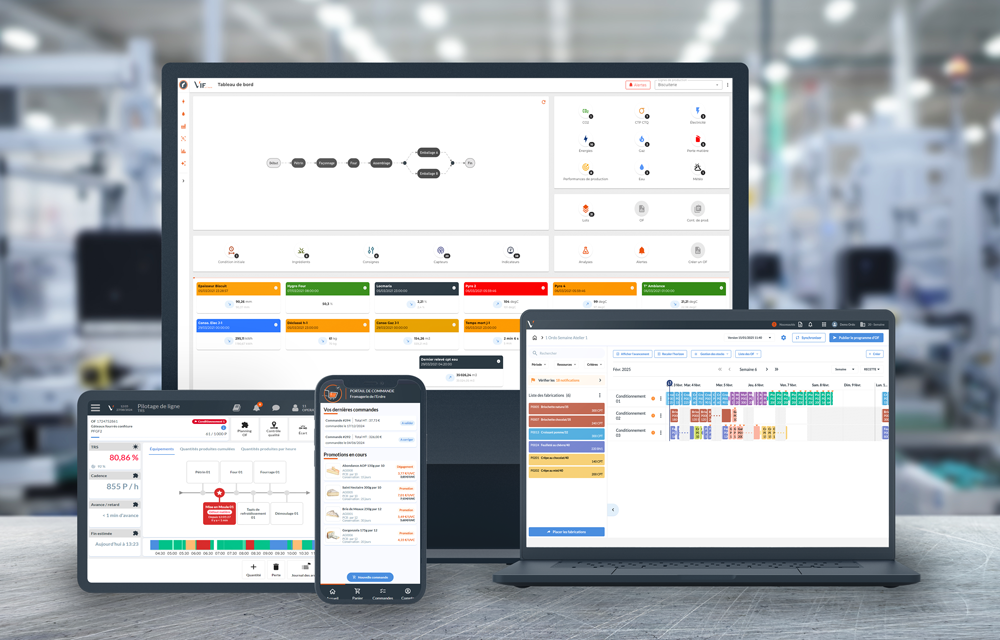

✅ Scheduling and production management software and an AI platform to maximise performance

✅ Video tracking of packaged products for flow analysis and dispute management

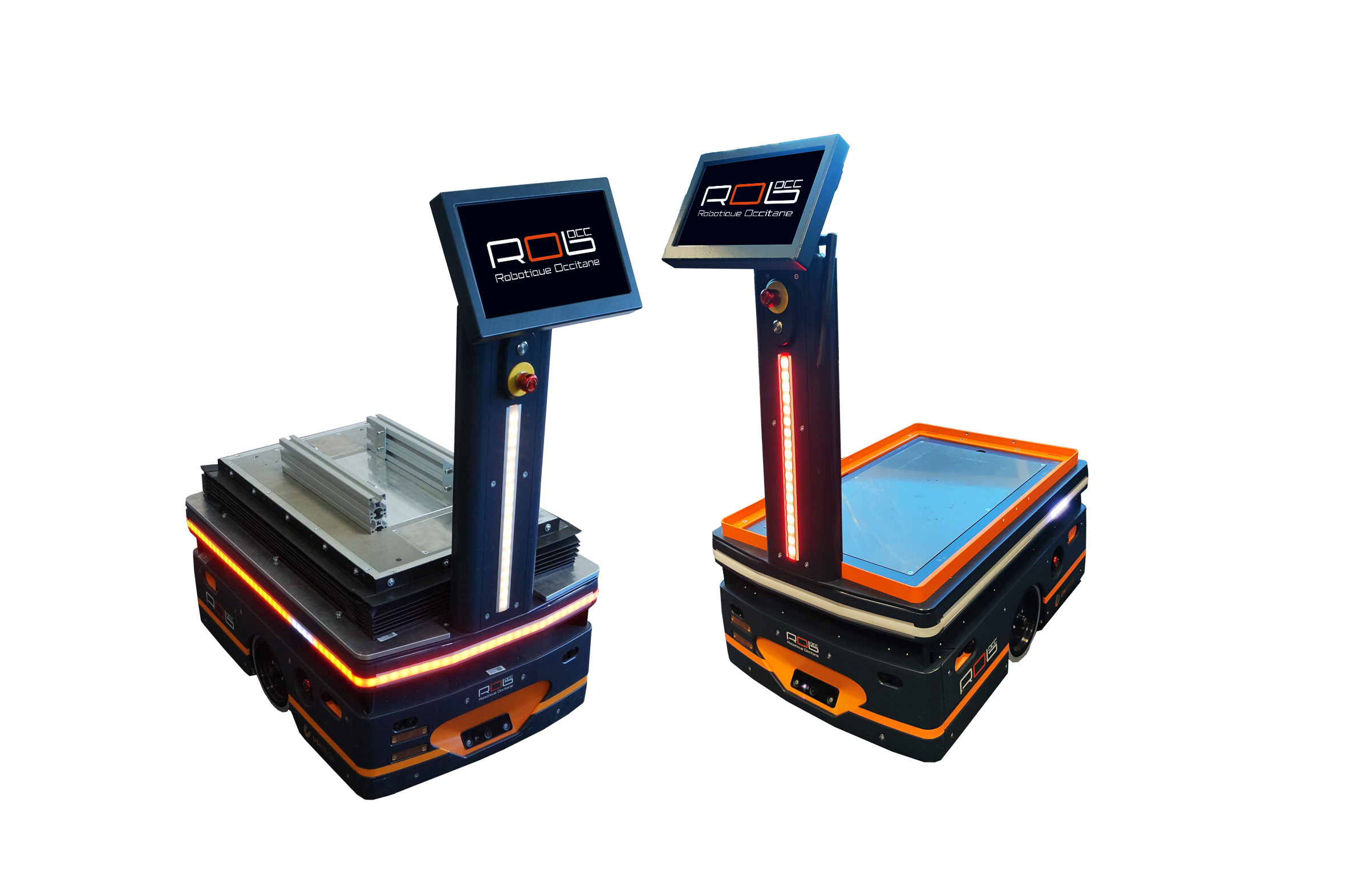

✅ Intralogistics provided by autonomous forklifts in fluid, productive and safe co-activity

✅ Transporting packaged products in reusable, durable, washable and traceable crates

✅ Cobots to eliminate arduous tasks and improve working conditions

✅ Marking solutions adapted to the transition to GS1's augmented QR-Code

They will be there

The showroom responded to industrial challenges and the 3Rs

Industrial performance

O² 2500 TWIN tray sealer equipped with two sealing stations, a key advantage in terms of flexibility and productivity.

Scheduling, production management and PowerOp platform to optimise production and energy performance in real time and help support growth.

The ROC-E is a cyber-secure Autonomous Intelligent Vehicle (AIV) that can be installed in less than an hour and adapts itself to all indoor factory environments.

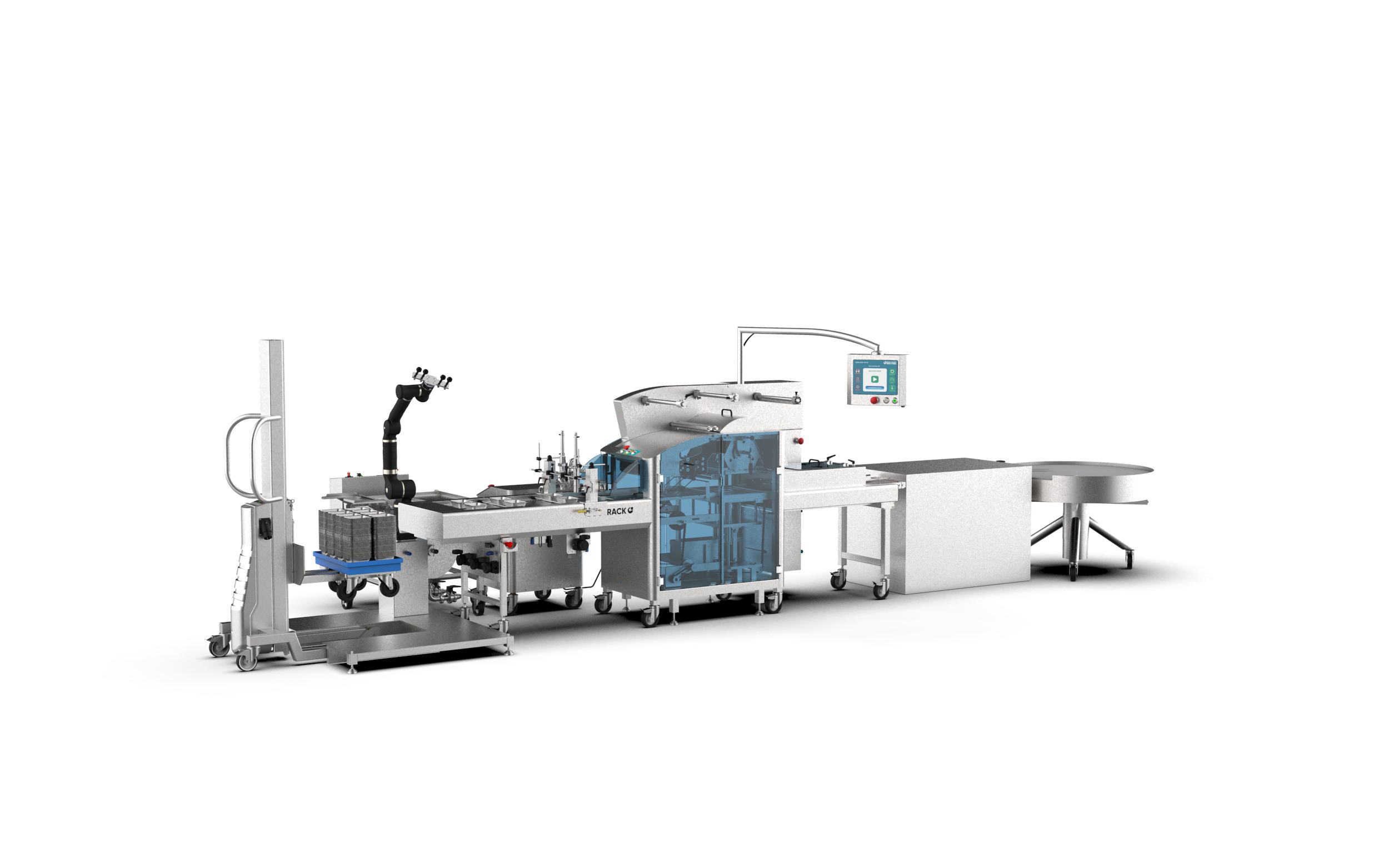

Automatic loading by a robot and retrieval by a cobot of sealed products to place them in handling bins.

The robotic pick & place island comprises a 6-axis collaborative robot combined with a gripper made up of 50% 3D-printed parts.

Proof through images: all packaged products will benefit from reliable real-time traceability with tangible guarantees.

Technologies capable of printing QR codes and variable data. Enough to usher in the era of delayed differentiation.

3R - Reduce, Reuse, Recycle

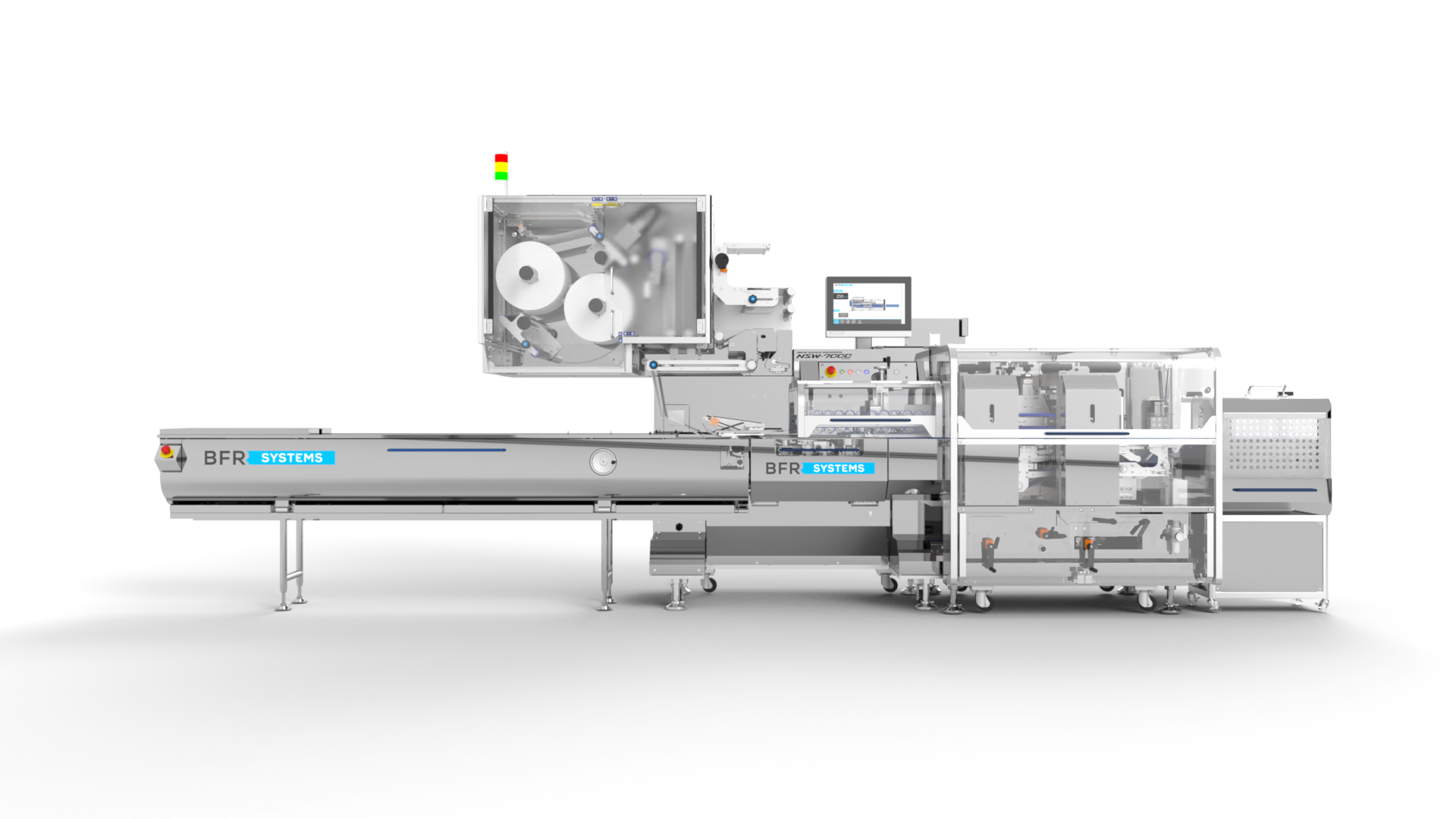

Designed for high-speed single-material packaging, the Omori NSW-7000 Flowpack adapts to paper solutions through the installation of customised formers.

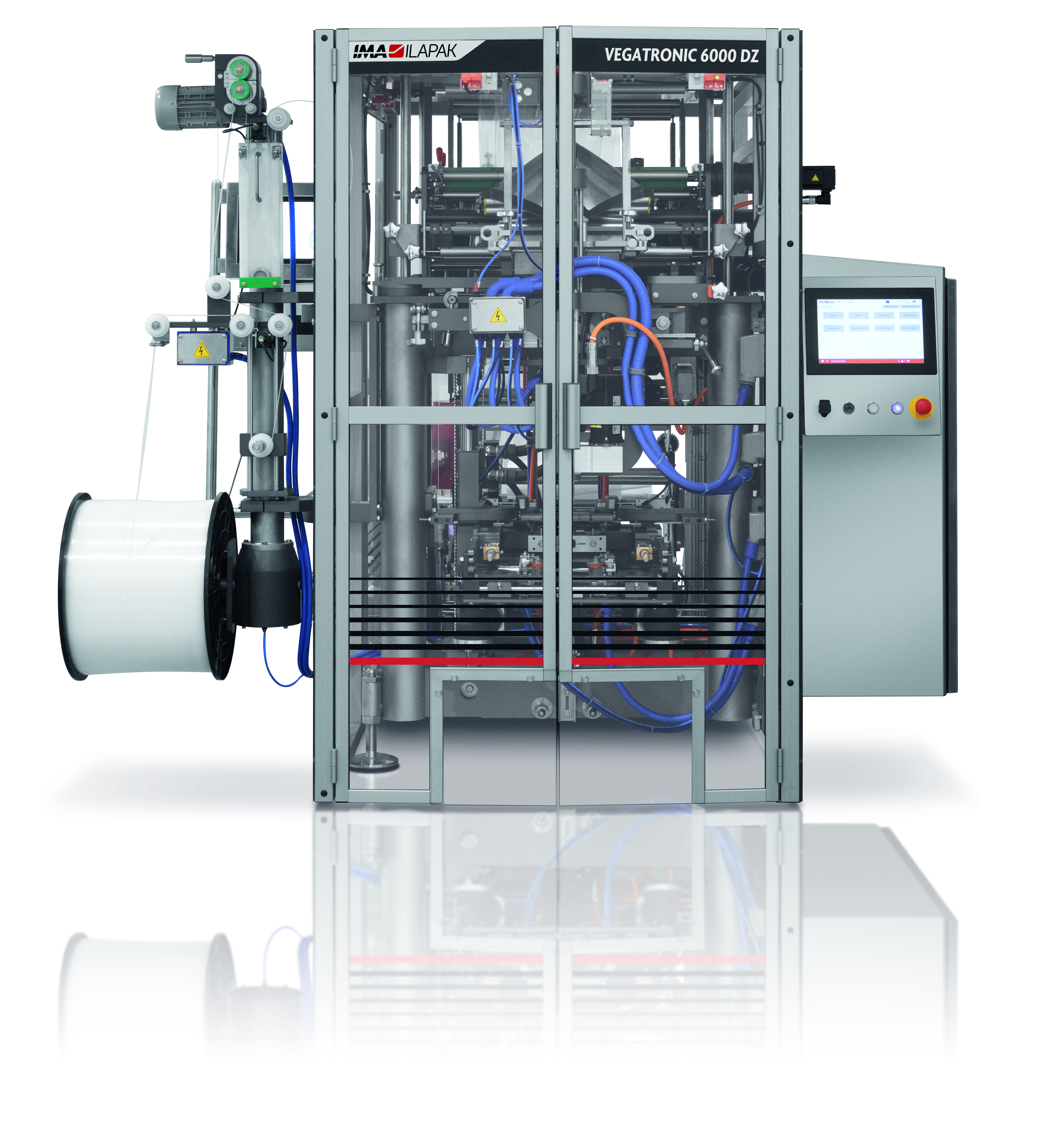

Suitable for a wider variety of packaging (e.g. single-material), the IMA Ilapak VegaTronic 6000 DZ continuous vertical form fill seal (VFFS) machine stands out for its quick format changeover, reduced to less than 5 minutes.

The DUOTRACK sealing machine heat seals a film developed specifically for reusable stainless steel trays.

Thanks to its water-based coating, PACKOKRAFT ECO heat-sealing paper stands out for its reduced PE content, targeted coating and optimised recycling.

Thanks to a dedicated packaging machine, VisioDune paper bags with windows reduce plastic use by up to 97% for packaging bread and pastries.

Reusable containers to reduce environmental impact and logistics costs, while ensuring accurate tracking of crates through the use of QR codes.

A cartoning machine four times smaller than the standard model